A top-quality industrial scale not only ensures accuracy and quality but increases daily productivity. Purchasing the right floor or platform scales is key to meeting both client needs and compliance requirements, and should result in increased efficiency and reliable measurements.

So, how exactly do you go about finding the best industrial scale for your business? Read on to find out!

Advantages of quality floor or platform scales

The production and supply process chain of industrial sectors is complex. The essential step of weighing components, parts, and equipment ensures success for the rest of the process, from quality control to shipment.

Top-quality scales ensure reliable results, boosting productivity through all steps of the production chain. A tailored weighing solution with effective technological features delivers many advantages:

- Improved efficiency

- Higher product quality, with minimal rejects

- Consistently accurate results

- Reliable weighing to save time and money

- Easy-to-use equipment

- Minimal maintenance and cleaning

Platform vs floor scales

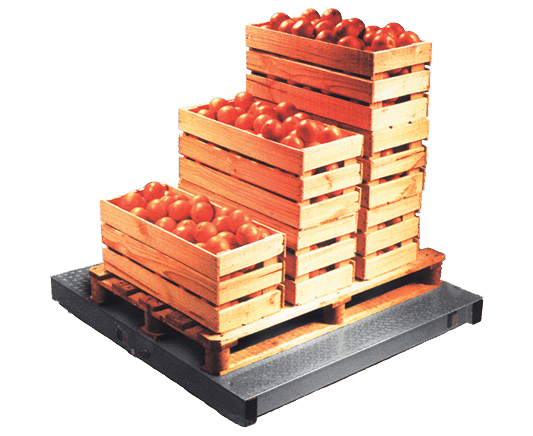

Platform scales are robust industrial weighing machines, raised off the ground and transportable. If your products are too heavy to easily lift off the ground onto a platform, then floor scales are the best option for you.

Floor scales are placed on a level surface or in a custom-fitted pit, enabling heavy or bulky goods to be weighed with ease. Both are suitable for a range of industrial requirements, from warehouses and factories to manufacturing and recycling plants.

Selecting the right scales for your needs

Choosing suitable industrial scales starts with clarifying your essential needs, from minimum size to whether it can measure your heaviest items without issue. It’s also important to take occupational health and safety considerations seriously, for example, if a factory deals with flammable materials then floor or platform scales designed for hazardous environments are essential.

Applications

First determine the main uses and applications for your new scale, which tasks it is intended for, and where it will sit in the production process. Common applications include:

- Weighing goods for shipment and integrity

- Counting and sorting according to weight classification

- Checking issues with goods, components, or quantities

- Management and supervision of the production process

- Recipe management via formulation and batching

Accuracy

Scales are essentially useless without reliable, accurate results that meet both regulated outcomes and client expectations, making it important to select a quality scale capable of meeting each requirement.

Accuracy relies on multiple quantifiable specs such as readability (the smallest available weight resolution), linearity (a scale’s variance in accuracy), and reproducibility (consistency of results).

Size and capacity

Always choose a scale that exceeds your requirements for size and weight capacity (the max mass it can weigh). Your heaviest item should sit in the middling range, well below the maximum weight requirement for industrial scale, ensuring accuracy and reliability.

Quality industrial scales from Instant Weighing

With a long-standing reputation for quality and professionalism, Instant Weighing supplies a range of superior platform and floor scales to help leading Perth industries.

Premium products like the Multi-functional Platform Scales HW-C / HW-CP provide accurate results along with multiple great features, including a built-in printer, LCD display, comparator lights, key locks, optional roller conveyors, and much more.

Purchase the Multi-functional Platform Scales HW-C / HW-CP online now, or contact the helpful team at Instant Weighing today with any queries.